Normally,the stamping is first and then lamination.

People often worry about the gold foil is easy to rub off and first stamping and then lamination, which is easy to cause: film (especially matte film) will destroy the surface gloss of the aluminum electrochemical, should not use water-soluble glue lamination, otherwise it will cause blackening of the aluminum electrochemical surface, while very easy to cause gold powder sticky in the edge of the graphics caused by the phenomenon of hair deficiency.

Stamping after the role of pressure and depression, coupled with the glue is not easy to penetrate the surface layer of aluminum electrochemical, easy to cause stamping at the film and paper separation and affect product quality. Hot stamping process is the use of the principle of heat pressure transfer, the aluminum layer in the aluminum electrochemical transfer to the surface of the substrate to form a special metal effect, because the main material used in hot stamping is aluminum foil, so hot stamping is also called aluminum electrochemical stamping.

Positioning holographic foil stamping. Holographic laser positioning electrochemical aluminum in the design is a special process application, with the corresponding anti-counterfeiting pattern, can greatly improve the anti-counterfeiting ability of the product, but also to improve the grade of the product.

This kind of electrochemical aluminum is generally produced domestically, and compared with foreign imports, the price is cheaper, but the stamping performance is slightly worse. Holographic laser positioning of aluminum electrochemical hot stamping temperature, hot stamping pressure and speed control, and even hot stamping machine type have a lot to do with

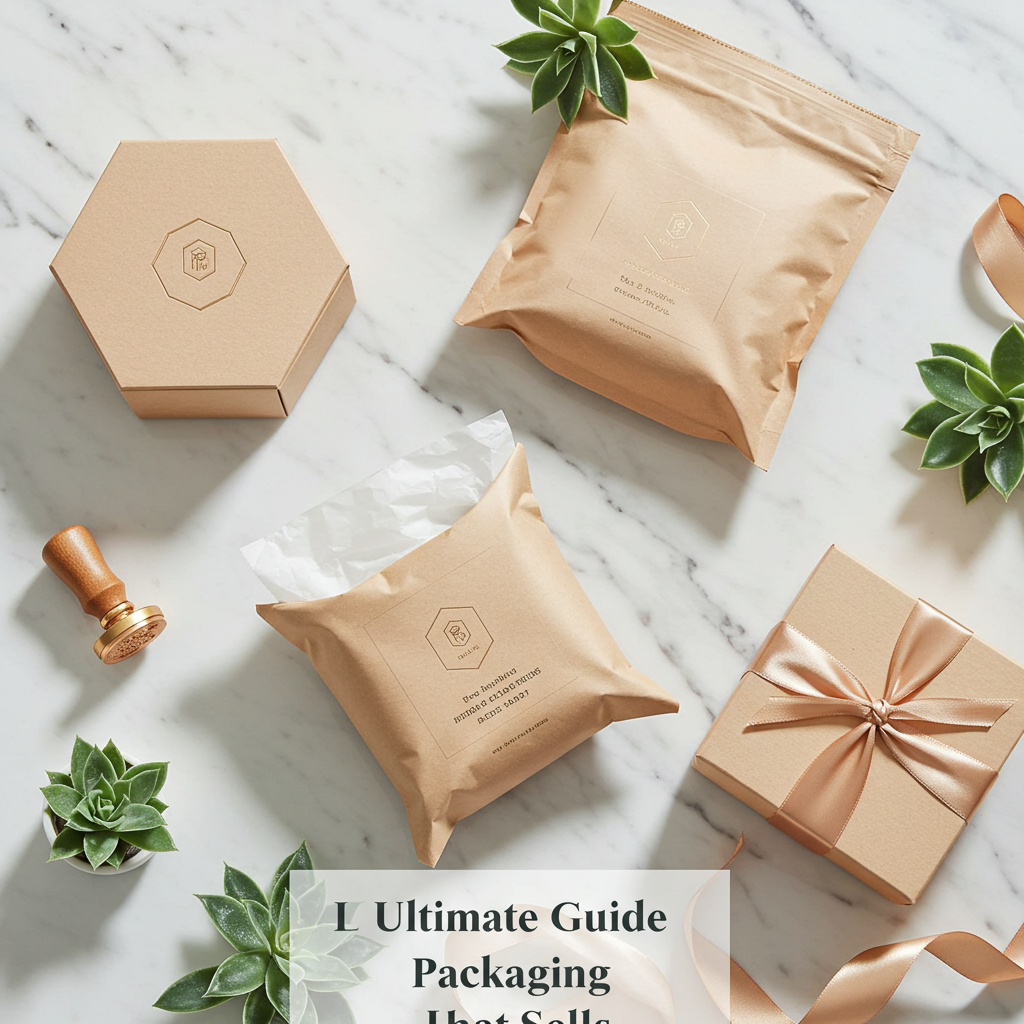

Hrenary packaging,10 years direct factory of customing paper package,can provide superb hot stamping golden/silver/copper on the face of wrapping paper,pls contact us for details.