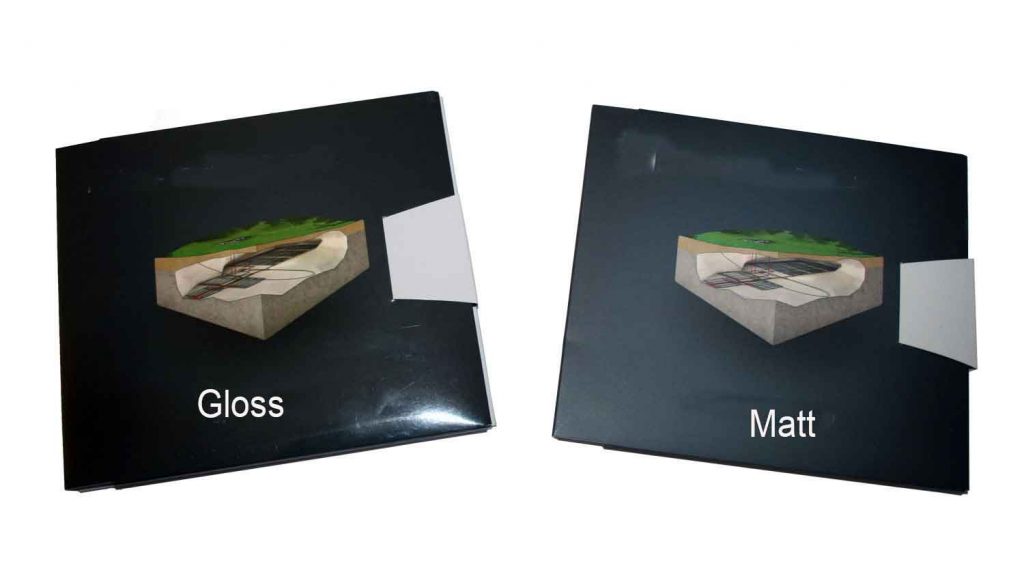

Lamination is common process of printing paperworks,which means applying a film to either one side or both sides of a printed documents.Normally,glossy lamination and matt lamination are two familiar lamination styles.

Why we use lamination in printing?

1. The lamination film can protect the printed paper well, make the surface more smoother, brighter,stain-resistant, water-resistant, wear-resistant.

2. After lamination, it can add luster or gloss on the printed paper matters,it is not easy to be worn. The abrasion resistance, folding resistance, tensile resistance and moisture resistance.

3. Lamination can make up for the quality defects of print matters. With lamination,some printing minor defects can be covered by the process of lamination.

Lamination type

Matt

This is a great no-shine finish that gives a subtle, smooth texture to your print. A very common finish often used on multi-use restaurant menus.

Matt lamination gives a subtle, tactile effect that oozes quality, great for items where image and first impressions mean everything.

Whilst forming a protective coating over the print, it does not provide the same level of protection as gloss lamination and can be prone to scratching and fingerprints especially where folding is involved.

Gloss

The opposite of matt, this is high-shine laminated printing like that used on glossy magazine covers.Gloss is more high profile, it adds a high gloss sheen often used on brochure covers, menus, magazine covers or presentation folders. It is definitely the high impact option. Gloss lamination forms a protective coating over the print which makes it suitable for items such as menus etc.

Hrenary packaging are 10 years experience factory of customizing paper package,more details pls contact hrenarypackaging@gmail.com

Itís hard to find well-informed people on this subject, but you seem like you know what youíre talking about! Thanks