Custom paper boxes are a cornerstone of branding and product presentation. However, many businesses fall into avoidable pitfalls during the ordering process, leading to delays, wasted budgets, or subpar results. As a trusted paper box and paper bag manufacturer, we’ve compiled the top five mistakes to watch out for—and how to avoid them.

1. Ignoring Material Specifications

The Mistake: Choosing the wrong paper type or thickness without considering the product’s weight, durability needs, or environmental factors. For example, heavy items may require corrugated cardboard, while lightweight cosmetics could use rigid box board.

The Cost: Fragile packaging risks product damage, while over-engineered materials inflate costs unnecessarily.

The Solution:

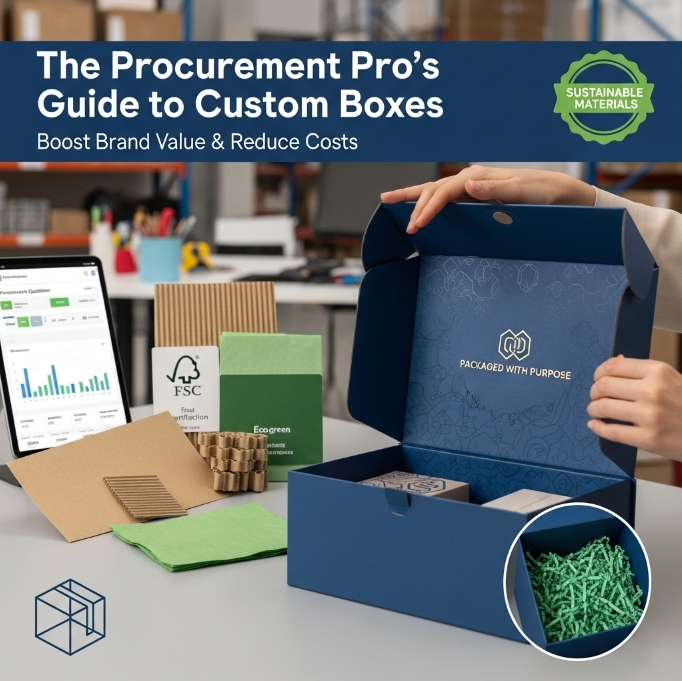

- Consult with your manufacturer early to match materials to your product’s requirements.

- Opt for eco-friendly options like recycled kraft paper or FSC-certified materials to align with sustainability goals.

2. Overlooking Design for Manufacturability

The Mistake: Submitting complex designs without verifying their feasibility for mass production. Intricate die-cut shapes or multi-layer printing may require specialized machinery or extended lead times.

The Cost: Delays in production or compromised design quality.

The Solution:

- Simplify designs by avoiding overly detailed graphics or non-standard box shapes.

- Use vector-based files (e.g., AI or PDF) and provide Pantone codes for color accuracy.

3. Neglecting Size Precision

The Mistake: Providing inaccurate dimensions, leading to ill-fitting boxes. A common example is failing to account for internal padding or product expansion.

The Cost: Increased shipping costs due to oversized boxes or product movement during transit.

The Solution:

- Measure your product precisely, including padding or inserts.

- Use industry-standard sizing tools or consult your manufacturer’s template library.

4. Underestimating Lead Times

The Mistake: Assuming custom orders can be rushed. Complex designs, specialty inks, or seasonal demand often extend production timelines.

The Cost: Missed product launches or rushed shipments with premium logistics fees.

The Solution:

- Plan ahead and confirm lead times with your supplier.

- Opt for modular designs that allow partial order fulfillment if timelines are tight.

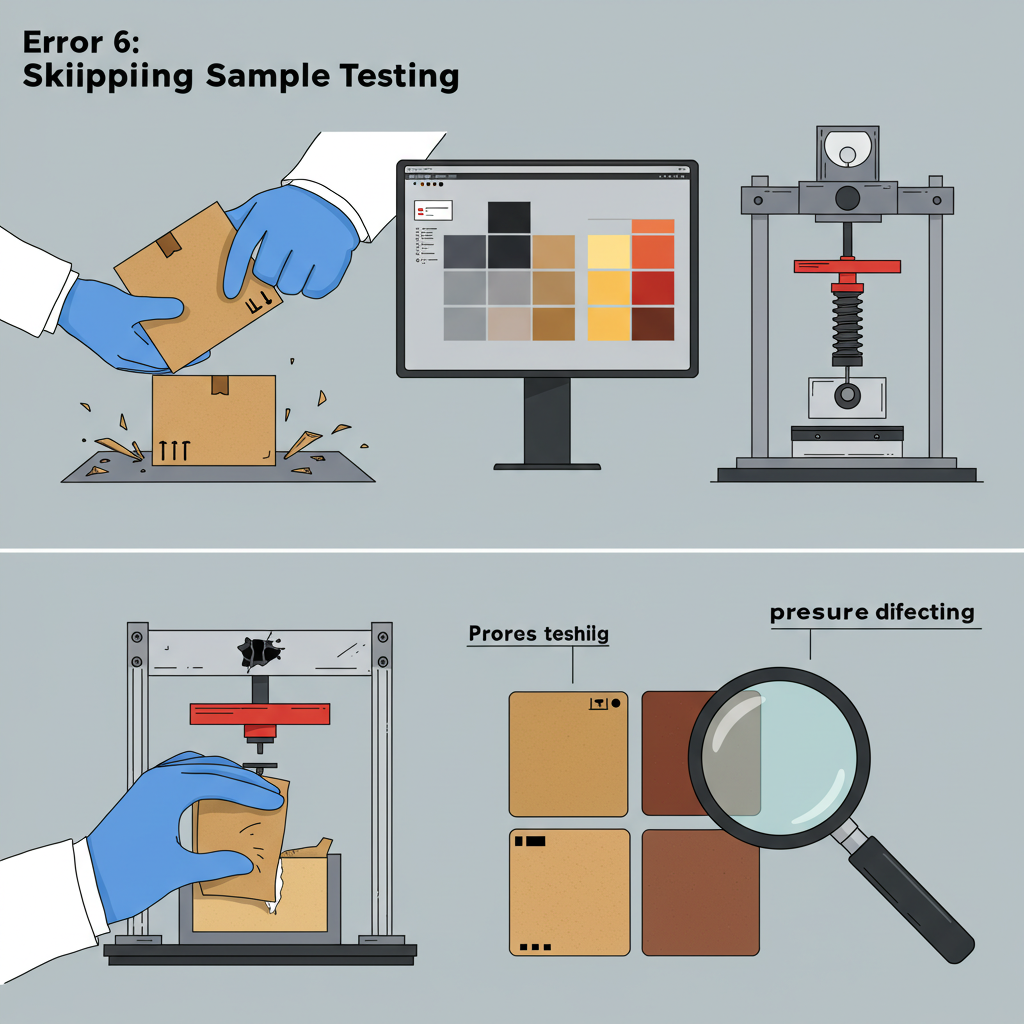

5. Skipping Sample Testing

The Mistake: Approving bulk orders without physical samples. Digital mockups may not reveal issues like color mismatches or structural weaknesses.

The Cost: Batch recalls or negative customer reviews due to quality issues.

The Solution:

- Always request a pre-production sample to test durability, print quality, and functionality.

- Conduct stress tests (e.g., drop tests for shipping boxes).

Avoiding these common mistakes can make a world of difference when it comes to your custom paper box orders. By paying close attention to material choices, design feasibility, precise sizing, realistic lead times, and thorough sample testing, you can ensure your packaging not only looks great but also performs reliably. At [Your Company Name], we’re here to guide you through every step of the process with expert advice and dependable service. Whether you’re launching a new product or scaling an existing one, smart packaging decisions start with the right partner. Let’s build packaging that elevates your brand—together.