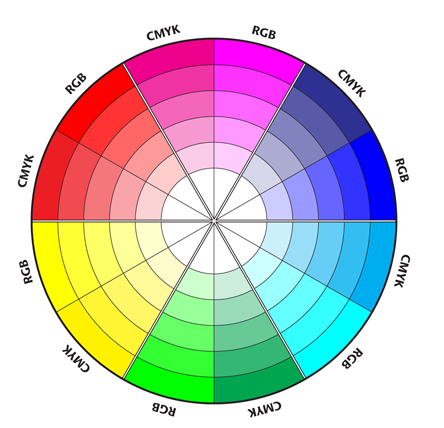

In the dynamic world of packaging design, the choice of printing methods plays a crucial role in determining the visual appeal and overall impact of a product on the shelves.Choosing the right printing method is crucial for creating packaging that is both visually appealing and cost-effective. Two popular printing methods for packaging are 4-color process printing and PMS (Pantone Matching System) printing. Each has its own advantages and disadvantages, so understanding the differences is essential for making the best choice for your product.

What is 4-Color Process Printing?

4-color process printing, also known as CMYK printing, is the most commonly used printing method for packaging. It utilizes four primary colors: Cyan (C), Magenta (M), Yellow (Y), and Black (K). These colors are combined in varying proportions to create a wide range of colors.

Pros of 4-Color Process Printing:

- Cost-effective: For designs with a wide range of colors, 4-color process printing is significantly cheaper than PMS printing.

- Versatile: 4-color process printing can reproduce millions of colors, making it suitable for complex designs with gradients and subtle color variations.

- Widely available: Most printing companies offer 4-color process printing, making it readily available and convenient.

Cons of 4-Color Process Printing:

- Limited color accuracy: Due to the limitations of the CMYK color space, some colors may not be accurately reproduced. This can be particularly problematic for brand colors or specific hues that are critical to the design.

- Dot gain and color shifts: The printing process can lead to slight variations in color, creating a “dotty” appearance or subtle color shifts, particularly on large areas of solid color.

- Not ideal for metallic or fluorescent colors: 4-color process printing cannot reproduce metallic or fluorescent colors, which may require additional printing techniques.

What is PMS Printing?

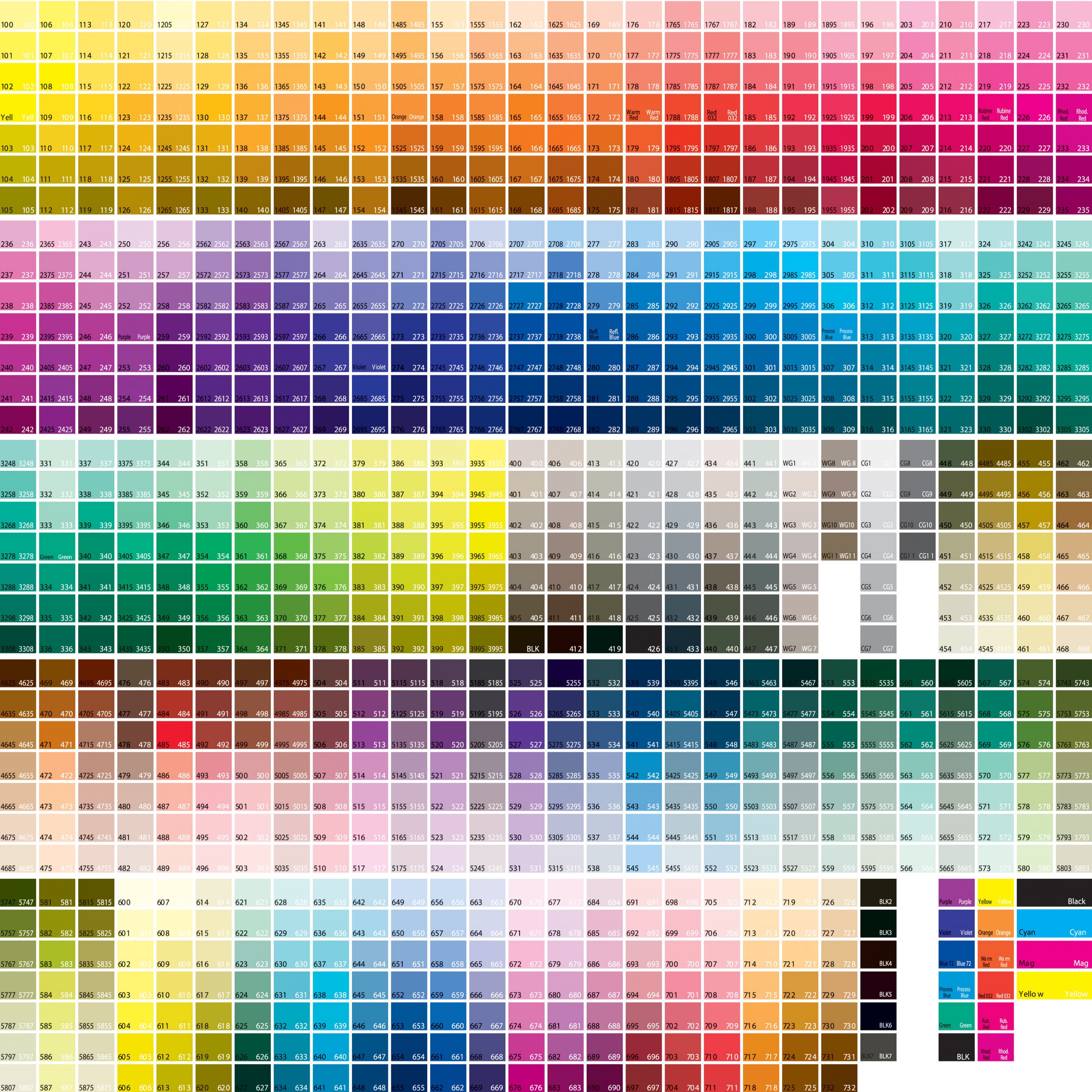

PMS printing uses pre-mixed ink colors according to the Pantone Matching System (PMS). Each PMS color has a unique identifier that ensures consistent and accurate color reproduction across different printers and materials.

Pros of PMS Printing:

- Accurate color reproduction: PMS printing guarantees precise and consistent color matching, making it ideal for branding purposes and designs with specific color requirements.

- Vibrant and rich colors: PMS inks are often more vibrant and saturated than colors produced by CMYK printing, adding a pop to the packaging.

- Metallic and fluorescent options: PMS offers a wider range of colors, including metallic and fluorescent options that are not possible with CMYK printing.

Cons of PMS Printing:

- Higher cost: Each PMS color requires a separate printing plate, making PMS printing significantly more expensive than 4-color process printing, especially for designs with many different colors.

- Limited flexibility: Since each color requires a separate plate, PMS printing is less flexible for designs with gradients or subtle color variations.

- Less widely available: Not all printing companies offer PMS printing, and it may require sourcing specialized printers or incurring additional setup fees.

Choosing the Right Printing Method:

The best printing method for your packaging depends on several factors, including:

- Budget: If your budget is tight, 4-color process printing is the more cost-effective option. However, if color accuracy is crucial, PMS printing may be worth the investment.

- Design complexity: For designs with a wide range of colors or gradients, 4-color process printing is the better choice. PMS printing is ideal for designs with specific color requirements or those using metallic or fluorescent colors.

- Desired color accuracy: If color accuracy is critical for your brand or design, PMS printing is the only way to guarantee consistent and accurate results.

- Available printing services: Consider the printing services available to you and their capabilities. Not all printers offer PMS printing, so ensure you choose a company with the necessary expertise and equipment.

Choosing between 4-color process printing (CMYK) and Pantone Matching System (PMS) depends on various factors, including budget, color accuracy requirements, and the intended visual impact. Designers need to carefully evaluate the specific needs of each packaging project to make an informed decision that aligns with the brand’s vision and budget constraints. Whether opting for the cost-effectiveness of 4-color printing or the precise color matching of PMS, a thoughtful approach to selecting the printing method will undoubtedly contribute to the overall success of the packaging design.