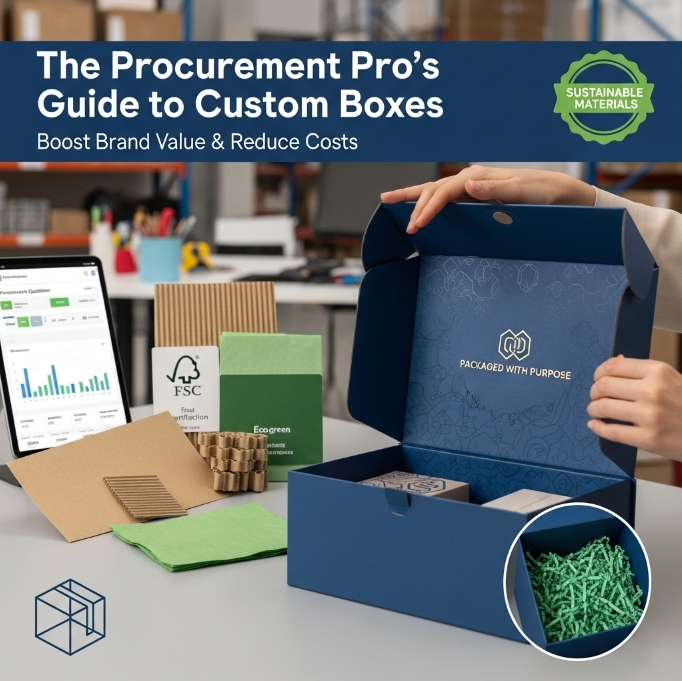

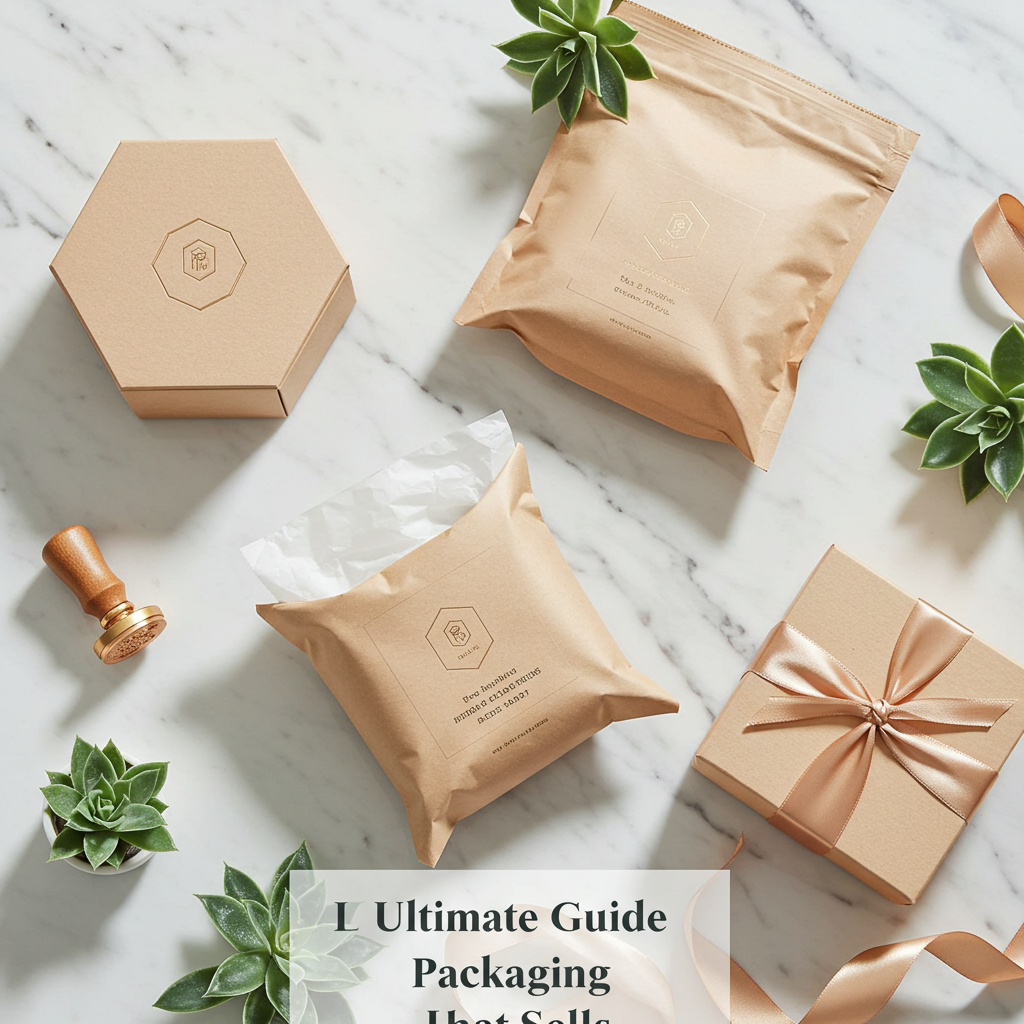

In the packaging industry, Custom Box Dimensions are the cornerstone of product safety, shipping efficiency, and brand perception. At Hrenary Packaging, a leader in High-Quality Box Manufacturing and Bespoke Packaging Design, we recognize that precision is non-negotiable. Whether crafting Eco-Friendly Paper Boxes for sustainability-driven brands or Luxury Rigid Box Production for premium goods, accurate measurements ensure flawless functionality and aesthetics. This guide unveils our expert methods for measuring Custom Box Dimensions, empowering you to create Precision Packaging Solutions tailored to your unique needs.

Why Are Custom Box Dimensions Critical for Success?

Today, Tailor-Made Paper Boxes aren’t just a technical necessity—they’re a strategic tool to align with market trends, consumer expectations, and brand elevation. Accurate measurements minimize design errors and elevate the unboxing journey, directly impacting:

1.Product Protection

Oversized boxes risk product movement; undersized ones compromise integrity.

2.Cost Efficiency

Precise sizing reduces material waste, aligning with Wholesale Packaging Boxes affordability.

3.Brand Loyalty

Perfectly fitted boxes enhance user experience, a hallmark of Custom Gift Box Supplier excellence.

At Hrenary Packaging, we merge innovation with practicality, ensuring every Custom Printed Packaging solution reflects your brand’s vision.

Step-by-Step Guide to Measuring Custom Box Dimensions

- Define Box Purpose & Type

Folding Boxes: Ideal for lightweight items like cosmetics (think Eco-Friendly Paper Boxes).

Corrugated Mailers: Optimal for electronics, leveraging durability.

Luxury Rigid Boxes: Crafted for high-end retail, combining protection with sophistication.

Hrenary Packaging offers Bespoke Packaging Design across styles, ensuring form meets function.

- Measure Product Dimensions

Length (L): Longest side.

Width (W): Secondary side.

Height (H): Shortest vertical edge.

Pro Tip: For irregular shapes, measure maximum dimensions.

- Calculate Internal Dimensions

Add 1-2mm to product measurements for easy insertion. - Factor in Material Thickness

Corrugated boards (1-5mm) or rigid materials impact external sizing. Our Precision Packaging Solutions team calculates this seamlessly. - Validate with Prototypes

Test with 3D-printed models or samples to ensure fit and functionality.

Hrenary Packaging’s Expert Insights

1.Functionality First

Add space for inserts or display windows—key for Custom Gift Box Supplier appeal.

2.Material Mastery

Choose between recycled kraft (for Eco-Friendly Paper Boxes) or rigid boards for luxury finishes.

3.Tech-Driven Accuracy

Leverage laser tools and 3D scanning in our High-Quality Box Manufacturing process.

4.Detail-Oriented Design

Consider folds, closures, and Custom Printed Packaging graphics during measurements.

Conclusion: Elevate Your Brand with Precision

Mastering Custom Box Dimensions is the foundation of impactful packaging. As a trusted Custom Gift Box Supplier and innovator in Luxury Rigid Box Production, Hrenary Packaging delivers end-to-end solutions—from measurement to delivery. Whether you seek Wholesale Packaging Boxes or limited-edition Tailor-Made Paper Boxes, our expertise ensures your products shine.

Ready to Transform Your Packaging? Partner with Hrenary Packaging and redefine excellence with Bespoke Packaging Design that marries precision, sustainability, and artistry.

Contact us today to explore Precision Packaging Solutions crafted for your success.