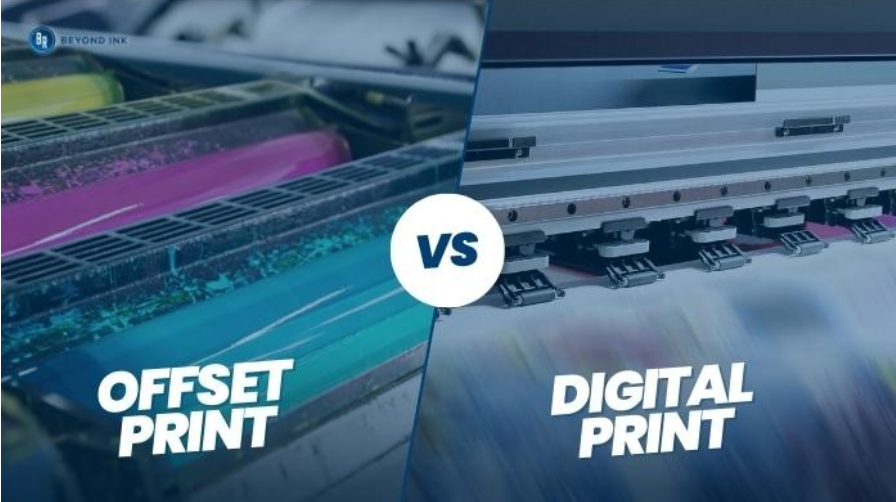

When it comes to packaging, choosing the right printing method can make a significant difference in the efficiency and effectiveness of your product branding. Offset printing and digital printing are two of the most commonly used methods for packaging. However, deciding between the two can be challenging, given their unique advantages and disadvantages.

In this article, we will provide a detailed comparison of offset and digital printing methods for packaging, highlighting the key pros and cons to help you make an informed decision.

Key Takeaways:

- Offset printing is ideal for high-volume print runs, offering precise color reproduction, and a cost-effective solution.

- Digital printing is perfect for shorter print runs, providing quick turnaround times, customization, and variable data printing capabilities.

- The cost per unit, print volume, and level of customization needed are primary factors to evaluate when choosing between offset and digital printing.

- Offset printing has higher initial costs and longer setup times, whereas digital printing may incur higher costs per unit for large print runs.

- Choosing the right printing method depends on your specific requirements, and by evaluating the right factors, you can make an informed decision to meet your brand’s packaging needs.

What is Offset Printing?

Offset printing or lithographic printing is a time-tested printing method widely used for high-volume printing projects, such as packaging. In offset printing, ink is transferred from a plate to a rubber blanket and then applied to the packaging material. This process ensures precise color reproduction and high-quality results, making it an ideal option for larger print runs.

Offset printing is widely used in the packaging industry due to its ability to produce consistent and high-quality results. In comparison to other printing methods, lithographic printing techniques provide superior coverage compared to digital printing.

One of the most significant advantages of offset printing is its ability to produce a large number of prints at an economical cost. Furthermore, if you’re looking for superior quality prints, then offset printing is the right choice for you.

Overall, offset printing is an ideal solution for packaging and other applications that require high-volume printing and superior quality prints.

Pros of Offset Printing for Packaging

Offset printing is a popular choice for packaging for several reasons:

| Pros | Description |

|---|---|

| High color accuracy | Offset printing produces consistent and vibrant colors for packaging, ensuring your brand has a professional look and feel. |

| Cost-effective for large print volumes | Offset printing is cost-effective for larger print orders. It becomes even more cost-effective as the print quantity increases, making it an ideal option for big packaging projects. |

| Printing on various materials | Offset printing is versatile and can print on various materials besides paper. This ability includes printing on specialized substrates, making it useful for different packaging requirements. |

Offset printing is, therefore, a reliable printing option for brands that need precise color accuracy and printing on a wide variety of materials. This method also offers brands a budget-friendly option, particularly for large print volumes.

Cons of Offset Printing for Packaging

While offset printing offers several benefits, it also has some notable drawbacks to consider. One significant disadvantage is the longer setup time required for the printing process compared to digital printing. This aspect makes it unsuitable for urgent or time-sensitive orders where a quick turnaround is necessary.

Additionally, offset printing involves higher initial costs, as it requires setting up and creating printing plates, which can be expensive. In contrast, digital printing technology eliminates the need for printing plates, making it a more cost-effective option for shorter print runs.

Another limitation of offset printing is the limited flexibility it provides for customization. Unlike digital printing, which enables easy personalization and variable data printing, offset printing requires significant adjustments to the printing plates, making it challenging to customize.

For those looking for a customizable, cost-effective, and efficient method for tag printing, digital printing is an ideal choice. However, large print volumes that need high color accuracy and consistent print results are better suited to offset printing.

What is Digital Printing?

In the world of packaging printing, digital printing is a relatively new but highly popular technology. It involves directly transferring digital files onto packaging materials, eliminating the need for printing plates. Digital printing can be viewed as on-demand printing because it enables shorter print runs with fast turnaround times.

Digital printing offers numerous advantages, including cost savings, flexibility, customization, and personalization. It is ideal for small- to medium-sized print runs, making it a top choice for brands seeking shorter runs. What’s more, digital printing eliminates the need for plates, the setup times for which can be significant, leading to quicker turnaround times.

Another benefit of digital printing is its ability to provide variable data printing. This capability allows brands to personalize each package with unique data, such as names, text, or images, without affecting the overall print run. This feature can be especially useful for marketing and promotional campaigns, where customers prefer personalized packaging.

Digital printing is a versatile and reliable option for packaging printing, offering fast turnarounds and customization capabilities that offset printing can’t match.

Pros of Digital Printing for Packaging

Digital printing has emerged as a reliable and versatile solution for packaging needs. The technology provides several benefits, making it an efficient and cost-effective option for brands.

Quick Turnaround

One of the most substantial advantages of digital printing is its quick turnaround time. It enables brands to meet time-sensitive orders and tight deadlines without compromising quality. Without the need for printing plates, the process is streamlined, and printing can commence quickly, ensuring orders are fulfilled at a heightened pace.

Cost-Effective for Small Runs

Another significant advantage of digital printing for packaging is its cost-effectiveness, especially for smaller print runs. In comparison to offset printing, which can be expensive for smaller projects, digital printing can provide a budget-friendly solution for such needs.

Design Flexibility

With digital printing, brands can showcase their packaging products’ unique designs, thanks to the technology’s flexibility. Various product designs can be efficiently printed, customized, and personalized with variable data printing capabilities. This capability ensures a personalized touch to products, making them stand out to their target audience. Moreover, digital printing can handle a wide range of materials, including plastics, films, and other specialized packaging substrates, allowing brands to experiment with various packaging materials without any constraint.

Cons of Digital Printing for Packaging

Although digital printing has many advantages over offset printing, it still has some limitations that are worth consideration. One of these drawbacks is color limitations. While digital printing technology has come a long way, it may not always achieve the same level of color accuracy as offset printing, which can affect the overall quality of the packaging.

Additionally, digital printing may incur higher costs per unit for larger print runs compared to offset printing. This is because digital printing technology relies on specialized inks and printing equipment, which could increase the overall production cost. However, digital printing is still a cost-effective option for smaller print runs with faster turnaround time, providing ample design flexibility and personalization options, including variable data printing.

Summary of Cons of Digital Printing for Packaging

| Cons of Digital Printing for Packaging | Description |

|---|---|

| Limited Color Accuracy | Digital printing may not attain the precise and vibrant color accuracy of offset printing. |

| Higher Cost per Unit | Cost-effectiveness of digital printing is best realized with small print runs, as larger runs can be more expensive compared to offset printing. |

It is worth noting, however, that advancements in digital printing technology have led to reduced limitations over time. Further improvements will make digital printing a more attractive option for brands that prioritize quality and cost-effectiveness in their product packaging.

Considerations for Choosing Between Offset and Digital Printing

When it comes to choosing between offset and digital printing for packaging, there are several factors to consider. The primary factors to evaluate include the cost per unit, desired print volume, and level of customization needed. But there are also other considerations such as the timeline and urgency of the order that should be taken into account to ensure the most appropriate printing method is chosen.

Let’s take a closer look at each factor:

Cost per Unit

One of the most important factors to consider when choosing between offset and digital printing is the cost per unit. For larger print runs, offset printing is typically more cost-effective due to the lower cost per piece. However, for smaller print runs, digital printing can be more cost-effective since there are no plates required and no setup time needed.

Desired Print Volume

Another critical factor is the desired print volume. Offset printing is more suitable if you need large quantities of packaging printed, as it can handle high-volume printing projects efficiently. Digital printing, on the other hand, is best suited for shorter print runs where a shorter turnaround time is crucial.

Level of Customization Needed

If your packaging requires a high level of customization, digital printing may be the better option. Digital printing allows for easy customization and personalization of your packaging and allows for variable data printing capabilities. Offset printing, while still customizable, may have some limitations in terms of the level of customization that can be achieved.

Timeline and Urgency of Order

Finally, timeline and urgency of the order should be taken into account when deciding between offset and digital printing. If you have an urgent order that needs to be printed quickly and efficiently, digital printing is likely the better choice due to its faster turnaround time. Offset printing requires more time for setup and plates, making it less ideal for urgent orders.

By considering your budget, print volume, customization needs, and order timeline, you can make an informed decision on the most appropriate printing method for your packaging needs.

Conclusion

In conclusion, choosing between offset and digital printing for packaging is a crucial decision that impacts your brand’s product presentation and image. The decision should be based on your specific needs, including budget, print volume, and customization requirements.

Offset printing is an excellent choice for high-volume print runs, offering precise color reproduction and a cost-effective solution. On the other hand, digital printing is ideal for shorter print runs, providing quick turnaround times and customization capabilities. It is also a suitable option for variable data printing needs.

Ultimately, the choice between offset and digital printing for packaging depends on your unique circumstances. Therefore, it is essential to evaluate your options and choose the one that aligns best with your requirements.

Make a sound decision on offset or digital printing for your packaging needs and elevate your brand’s image to a new level today.

FAQ

What are the key considerations when choosing between offset and digital printing for packaging?

The key considerations when choosing between offset and digital printing for packaging include factors such as cost, print volume, customization needs, and timeline.

What is offset printing?

Offset printing, also known as lithographic printing, is a traditional printing method used for high-volume printing projects. It involves transferring ink from a plate to a rubber blanket before being applied to the packaging material.

What are the pros of offset printing for packaging?

The pros of offset printing for packaging include high color accuracy, cost-effectiveness for large print volumes, and the ability to print on various materials.

What are the cons of offset printing for packaging?

The cons of offset printing for packaging include longer setup time, higher initial costs, and limited flexibility in customization compared to digital printing.

What is digital printing?

Digital printing is a modern printing method that involves directly transferring digital files onto packaging materials. It is often used for on-demand printing and shorter print runs.

What are the pros of digital printing for packaging?

The pros of digital printing for packaging include quick turnaround time, cost-effectiveness for small print runs, and design flexibility for customization and personalization.

What are the cons of digital printing for packaging?

The cons of digital printing for packaging include color limitations compared to offset printing and potentially higher costs per unit for larger print runs.

What should be considered when choosing between offset and digital printing?

When choosing between offset and digital printing, factors such as cost, print volume, customization needs, and timeline should be considered to make an informed decision.

What is the conclusion for choosing between offset and digital printing for packaging?

The choice between offset and digital printing for packaging depends on specific requirements. Offset printing is beneficial for high-volume print runs, offering precise color reproduction and cost-effectiveness. Digital printing is ideal for shorter print runs, providing quick turnaround times, customization, and variable data printing capabilities.