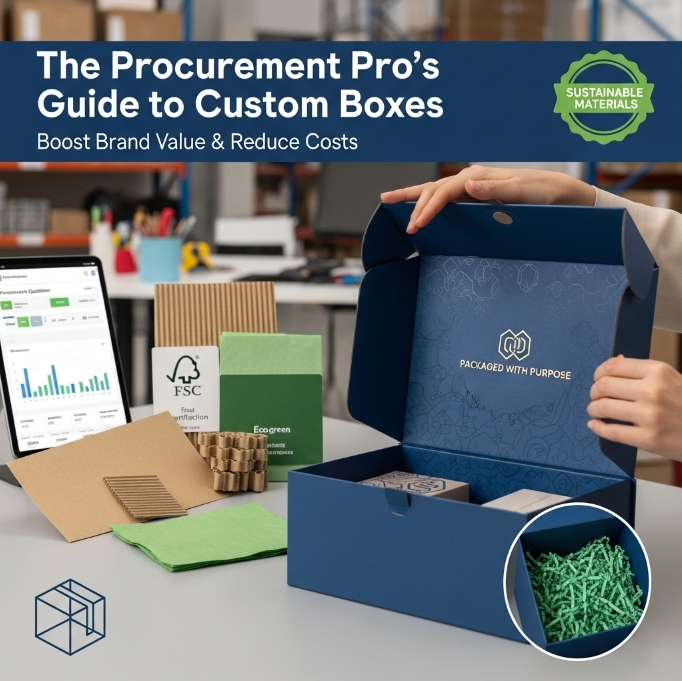

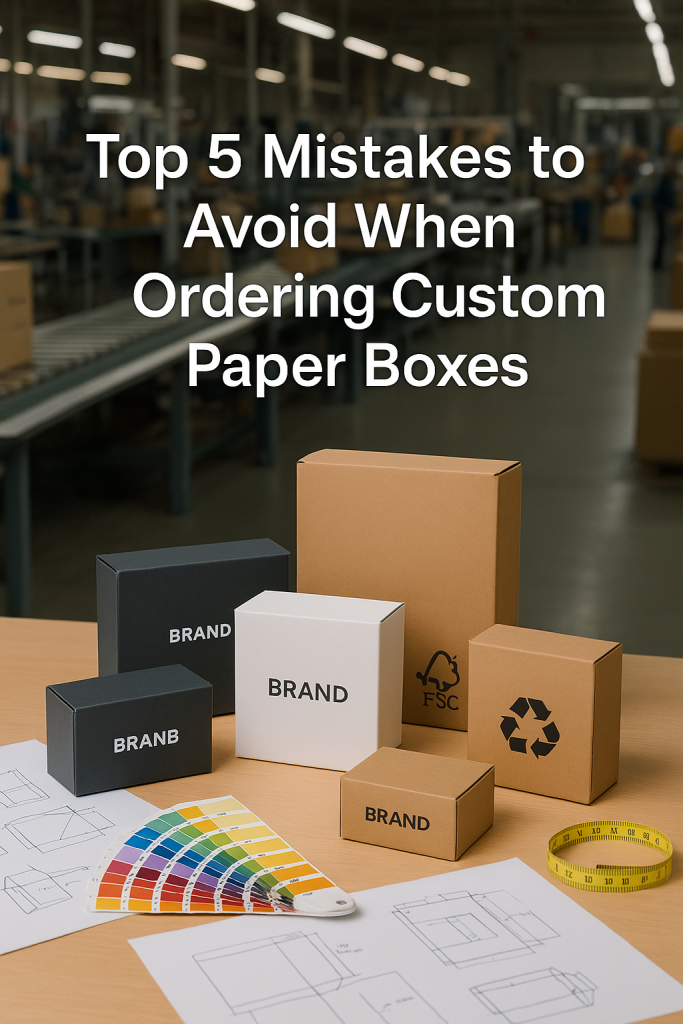

Custom packaging is more than just a container—it’s a silent ambassador for your brand. From enhancing unboxing experiences to ensuring products arrive safely, packaging plays a pivotal role in shaping customer perceptions. However, balancing aesthetics, functionality, and budget requires understanding three critical factors: MOQ (Minimum Order Quantity), Size, and Finishing. In this guide, we’ll break down how these elements impact costs and share actionable strategies to optimize your packaging investments.

I. What is MOQ and Why It Matters

MOQ refers to the minimum number of units a manufacturer requires for a single order. For custom packaging, MOQs exist because setting up production (e.g., creating molds, printing plates, or adjusting machinery) involves upfront costs.

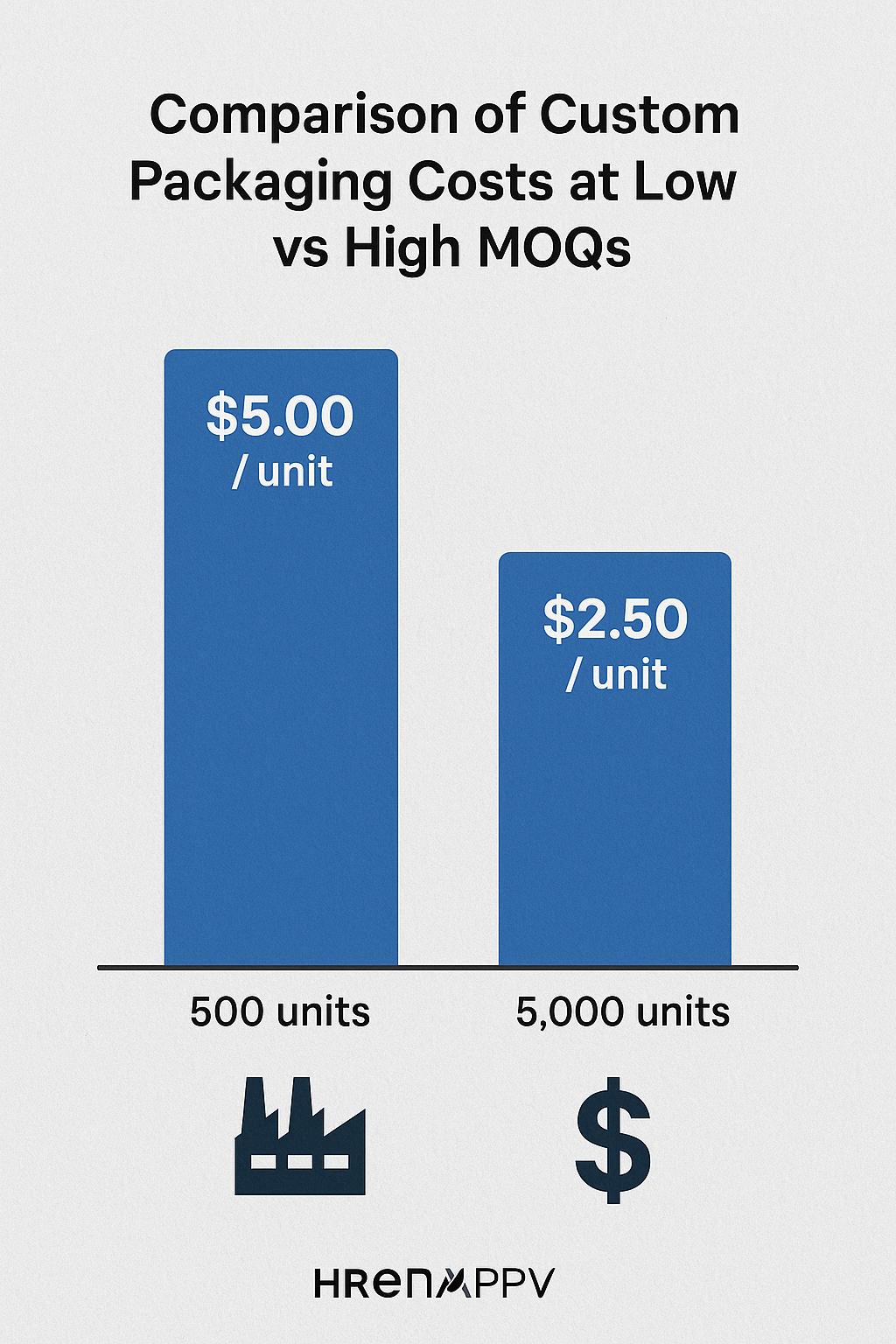

How MOQ Affects Costs

- Lower MOQs (e.g., 500 units) often mean higher per-unit prices. Factories spread setup costs over fewer units.

- Higher MOQs (e.g., 10,000 units) reduce per-unit costs due to economies of scale.

Example:

A simple rigid box might cost 5per unit at500 pieces but drop to 2.50 per unit at 5,000 pieces.

Tips for Startups and Small Businesses

- Negotiate flexible MOQs: Some suppliers offer tiered pricing for growing businesses.

- Opt for stock designs: Use pre-existing templates to reduce setup fees.

- Partner with factories that specialize in low MOQs without compromising quality.

II. How Packaging Size Impacts Cost

Size directly influences material usage, production complexity, and logistics.

Material Costs

Larger boxes require more raw materials (e.g., paperboard, ink). For instance, a 12x8x4-inch box uses 30% more material than a 10x6x3-inch version, increasing costs proportionally.

Shipping and Storage

Oversized packaging raises shipping fees due to dimensional weight pricing. It also occupies more warehouse space, adding storage costs.

Case Study: Optimizing Size

A skincare brand reduced its box size by 20% to fit products snugly. This cut material costs by 15% and shipping expenses by 25%, saving $8,000 annually.

Key Takeaway: Work with your manufacturer to design right-sized packaging that protects products without excess bulk.

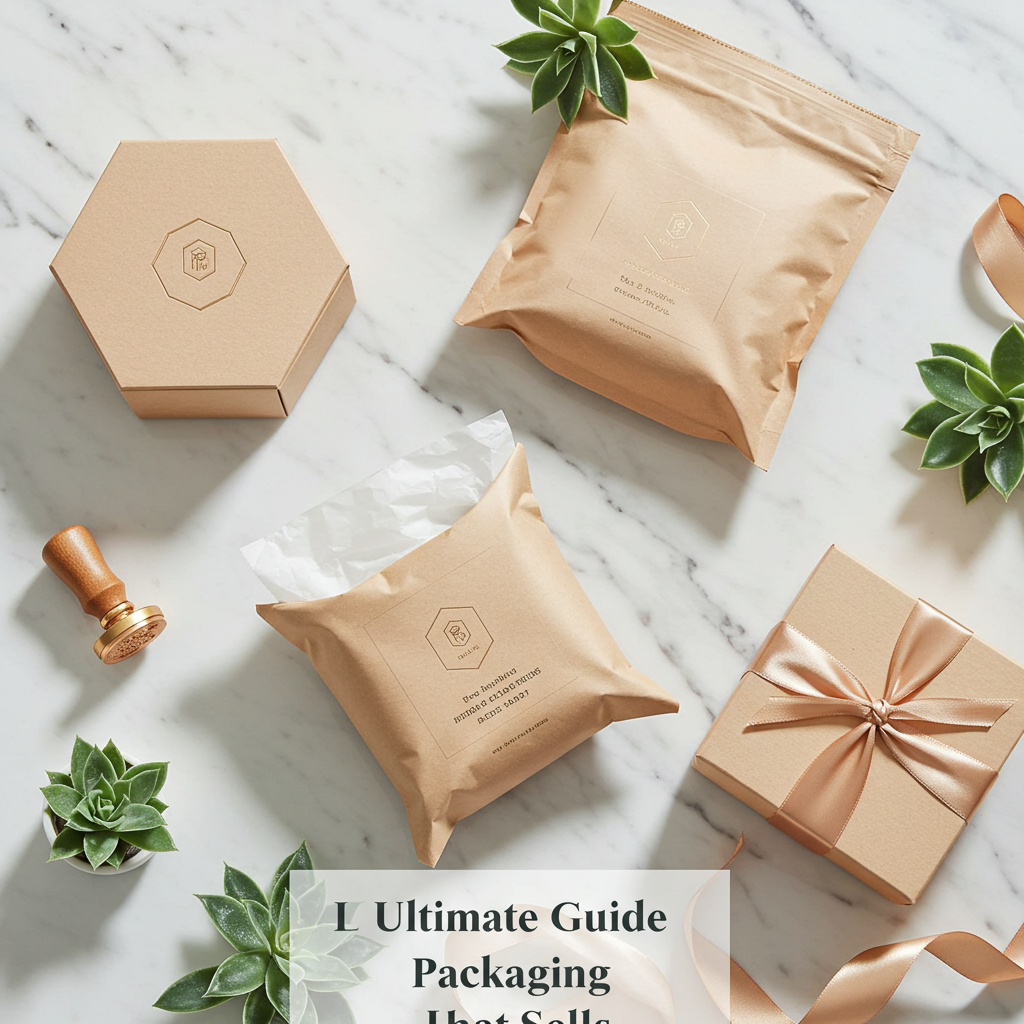

III. The Role of Finishing in Packaging Cost and Branding

Finishing refers to post-production treatments that enhance aesthetics and durability. Common options include:

- Basic Finishes: Matte/gloss lamination, aqueous coating.

- Premium Finishes: Embossing, foil stamping, spot UV, soft-touch coatings.

Cost Differences

- Basic finishes add 0.10–0.10–0.50 per unit.

- Premium finishes like foil stamping can cost 0.80–0.80–2.00 per unit.

When to Invest in Premium Finishing

Luxury brands or seasonal gift boxes benefit from finishes that elevate perceived value. For example, a gold-foiled logo on a rigid box signals exclusivity, justifying a higher price point.

Pro Tip: Use finishes strategically. Apply spot UV only to logos or key graphics instead of full coverage.

IV. Cost Breakdown Examples

1. Simple Kraft Paper Box (Low MOQ)

- MOQ: 500 units

- Size: 8x6x2 inches

- Finishing: Matte lamination

- Cost: $3.20 per unit

- Total: $1,600

2. Luxury Gift Box (High MOQ)

- MOQ: 5,000 units

- Size: 10x8x3 inches

- Finishing: Embossed logo + gold foil stamping

- Cost: $6.50 per unit

- Total: $32,500

| Factor | Simple Box | Luxury Box |

|---|---|---|

| MOQ | 500 | 5,000 |

| Unit Cost | $3.20 | $6.50 |

| Finishing | Matte lamination | Foil + embossing |

| Perceived Value | Functional | Premium |

V. How to Reduce Custom Packaging Costs

- Optimize MOQ: Order slightly above MOQ to qualify for bulk discounts.

- Standardize Sizes: Use common dimensions to avoid custom die-cutting fees.

- Simplify Finishing: Limit premium treatments to focal areas.

- Leverage Supplier Expertise: Experienced factories can suggest cost-saving design tweaks.

VI. Why Work with an Experienced Chinese Factory

With 10+ years in paper packaging, Hrenary Packaging offers:

- End-to-End Solutions: Design, prototyping, production, and global shipping.

- Flexible MOQs: Catering to startups and enterprise clients.

- Quality Assurance: ISO-certified processes and rigorous inspections.

Client Testimonial:

“Switching to Hrenary Packaging saved us 30% on packaging. Their team optimized our box design and delivered flawless prints every time.” – James, Eco-Friendly Apparel Brand

VII. Conclusion

MOQ, size, and finishing are the trifecta of custom packaging costs. By optimizing these factors and partnering with a trusted manufacturer, businesses can achieve premium quality without overspending. Whether you’re a startup testing the market or an established brand scaling up, strategic packaging decisions drive both savings and customer loyalty.